Hydrogen Fuel Cells

A fuel cell (FC) is a device that converts the chemical energy from a fuel into electricity through a chemical reaction. The reaction can be carried out with oxygen or another oxidizing agent. There various types of fuel cells are differentiated from each other by their electrolytes. Among these fuel cell technologies, hydrogen powered fuel cells have drawn special interest for their attributes of zero-pollution at point of use, high energy-conversion yields (up to 60% conversion efficiency), low operating temperature (50~100C), low noise, and renewability. If the heat generated is recovered for heating purpose, the overall efficiency of hydrogen fuel cell can be as high as 85%. Due to these advantages, hydrogen fuel cells are widely adopted for stationary, transportation, and portable applications. Another attribute of the hydrogen fuel cell is energy storage, which can be used as a buffer for renewable energies which are unstable such as PVs or wind turbines. Part of the energy at peak production can be used to generate hydrogen, which can be used to generate electricity through the fuel cell when the climate is unsuitable for power generation.

In a hydrogen fuel cell, air cool and water cool options are available to take care of the heat generated. In general, water cooled fuel cells are more reliable, although they cost higher than their air-cooled counterparts. Lilium energy Inc. carries water cooled fuel cells and software that monitors the performance and, if used as a backup application, switches the power on automatically during a power outage.

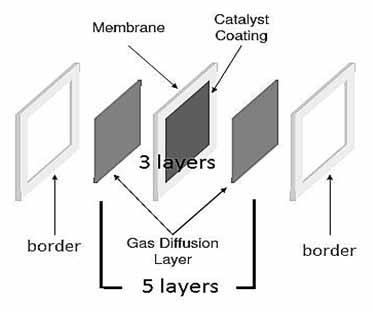

Hydrogen fuel cells utilize proton exchange membrane (PEM) as the electrolyte. The PEM coated with platinum/C as catalyst to decompose hydrogen molecule and gas diffusion layer (GDL) is called the membrane electrode assembly (MEAs), which is the key component of the fuel cells. Our PEM MEA has an innovative chemistry and coating technologies jointly developed in Taiwan by researchers at Chang Gung University and Mingchi University. This proprietary technology platform allows us to offer first-tier 3-layer and 5-layer MEAs in various dimensions with competitive pricing. Our MEA can be used in ambient environment and without moisturizing hydrogen or compressing the air.

Proton Exchange MEA

Proton exchange membrane fuel cells, also known as polymer electrolyte membrane fuel cells (PEMFC), were specifically developed for lower temperature and pressure application. The slate of applications include transportation, stationary, and portable devices. The key characteristic of PEM is a special polymer electrolyte membrane.

Within the membrane electrode assembly (MEA), the PEM is sandwiched between two electrodes that are coated by catalysts. The electrodes are insulated from each other by the membrane. These two electrodes make up the anode and cathode respectively. The PEM is proton permeable but electrically insulating. This barrier allows for the transport of the protons from the anode to the cathode through the membrane but forces the electrons to travel around a conductive path to the cathode.

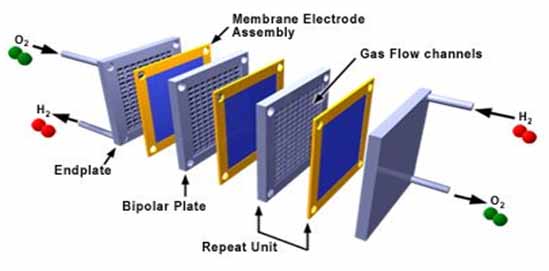

A stack is then assembled with multiple layers of MEAs, bipolar plates and end plates, this is the power generation core component in a fuel cell.